rockwell hardness test nptel|rockwell hardness testing procedure : ODM Mechanical Properties (Hardness Test)Prof. Ratna Kumar Annabattula Department of Mechanical Engineering IIT MadrasHardness Test Uncensored - JavRave.club – Japanese Porn – Watch XXX J.

{plog:ftitle_list}

According to one of the search results, Peter Thurnwald’s age is mentioned as 49 years old. However, it’s important to note that the exact birthdate is unknown and may not be explicitly stated in the available sources. Ver mais

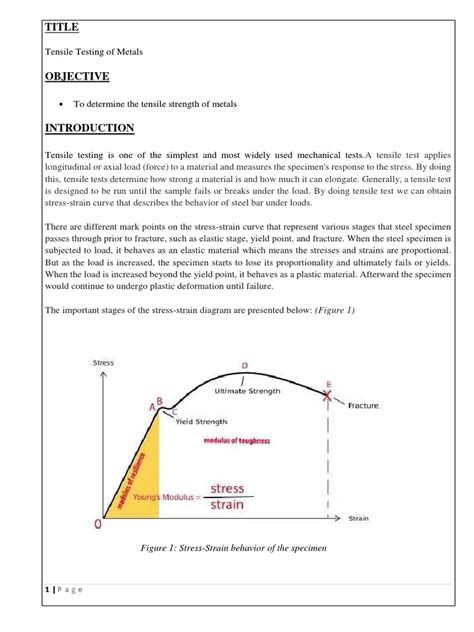

tensile testing pdf

Mechanical Properties (Hardness Test)Prof. Ratna Kumar Annabattula Department of Mechanical Engineering IIT MadrasHardness Test

The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented .Indirect Method for UCS, Brazilian Test, Schnidt Rebound Hardness Test. Sound Velocity Test, Slake Durability Test, Swelling Pressure and Free Swell Test & Void Index Test. Shear Tests .hardness is defined on the basis of the type of indenter, load used and the size of the impression left on the material. Three most commonly used indentation hardness scales are known as .

Afrormosia moisture meter

tensile test module pdf

Rockwell hardness tester presents direct reading of hardness number on a dial provided with the machine. Principally this testing is similar to brinell hardness testing. It differs only in diameter and material of the indenter and the applied .

For instance, the severity of quench, examined using a Rockwell hardness test, requires a part of sample be cut from the part being inspected. Non-Destructive Testing (NOT) methods help the .The hardness of a material by this Rockwell hardness test method is measured by the depth of Penetration of the indenter. The depth of Penetration is inversely With the Brinell hardness test, a carbide ball is pressed into the material. The indentation surface serves as a measure of the hardness. Vickers hardness te.These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to Rockwell Hardness Conversion Table

A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should .

1. Define hardness. What is Mohs scale of hardness? 2. Why it is necessary to specify load-indenter combination in Rockwell hardness test? 3. How is Brinell hardness measured. Show that BHN varies as P/D2 where P is the load and D is the indenter diameter. 4. Why is the included angle between opposite faces of the Vickers indenter 136 ? 5.Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness TestingSee also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .

Indirect Method for UCS, Brazilian Test, Schnidt Rebound Hardness Test: Download: 15: Sound Velocity Test, Slake Durability Test, Swelling Pressure and Free Swell Test & Void Index Test: Download: 16: Shear Tests - 1: Download: 17: Shear Tests - 2: Download: 18: Engineering Classification of Intact Rocks, Concept of Rock Mass, RQD: Download: 19 Destructive Testing Methods | Comparison Between Brinell, Rockwell & Vickers Hardness TestingRockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. .

African Mahogany moisture meter

Rockwell hardness test is one of the most common indentation hardness tests developed for hardness testing. In contrast to the Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). The minor load establishes the zero position .

The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine knives. How Rockwell Hardness Gets Measured.

What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .

The Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on surfaces with moderate roughness, making it a practical choice for a wide range of materials and surface conditions. In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm .

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find . The Rockwell hardness test involves making an indentation on the test material. The indenter is either a conical diamond or a steel ball. Indenter ball diameters range from 1/16 to 1/2 inches and are chosen based on the test parameters.

Indenters in a Rockwell hardness test are either hardened steel balls or a conical diamond. Two sets of loads cause an impact on the material surface, which include an initial minor load and a final major load. Additionally, the impact often causes an indentation on the material surface, and measuring the depth of this indentation helps to . The concept of the Rockwell Hardness test is essentially similar to its counterparts. A sample material is fed on to either a digital or manual Rockwell hardness tester which would then drop a set load ending with an indenter on the surface. Then, the strength of the material will be determined by the nature of the indentation left on the sample.The Rockwell hardness test is applied globally for the application of an experimental indentation hardness test. The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material). The Rockwell hardness test is a simple process that is why it can be performed by anyone .

measure its physical properties like hardness, tensile strength. For instance, the severity of quench, examined using a Rockwell hardness test, requires a part of sample be cut from the part being inspected. Non-Destructive Testing (NOT) methods help the analysis of components without causing permanent damage to it. Rockwell Hardness Test. The Rockwell hardness test is a widely used method for determining material hardness, especially in high-volume testing environments, due to its speed, simplicity, and efficiency. It provides direct hardness readings without the need for additional calculations, making it ideal for routine quality control.Load: The Rockwell hardness test uses a pre-load of 10 kgf, followed by the application of the main load, which varies depending on the Rockwell scale being used (e.g., 60 kgf for the Rockwell A scale, 150 kgf for the Rockwell C scale). The load is applied for a .spect to fatigue strength, hardness, and tensile and yield strength. MacGregor’s two-load was used for deter-mination of the true stress-strain curve for alloy 625 at room temperature. The two-load test requires no strain measurement during the test, and only the maximum and fracture loads are recorded. Data for

ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness . The rockwell hardness test is commonly used to measure the hardness of steel, which is crucial for kitchen knives. Knives with higher rockwell hardness scores are generally tougher and more resistant to wear and tear. On the other hand, blades with lower hardness scores may be more flexible and less prone to chipping. .

rockwell hardness testing procedure

Fatal Model na mídia. Está a procura de acompanhantes fem.

rockwell hardness test nptel|rockwell hardness testing procedure